Consulting

KNIGHT WENDLING GmbH, a sister company of GEMCO Engineers, is one of the leading consulting firms in the cast metals industry with special focus on the worldwide foundry industry.

An extensive worldwide network and in-depth market expertise enable the company to provide comprehensive consulting services and engineering know-how.

Strategic and Operational Expertise as PART OF THE SOLUTION

YOUR STRATEGIC PARTNER

"...We decided for Knight Wendling because of their foundry know-how and in-depth market expertise in the worldwide Metal Industry.

Their involvement over the years has been essential to determine the strategic direction of our company, maintain continuity, improve our results and strengthen our position ..."

- what customers say about us -

Corporate Strategy

Knight Wendling has worked throughout the world, helping clients to resolve issues of:

- Market assessments

- New product opportunity reviews

- Pricing and distribution

- Competitor benchmarking

- Production and process technology

- Restructuring

- Dedicated production

- Feasibility and capital investment reviews

- Site selection for new facilities

- Provision of added-value services

- Human resourcing

Mergers & Acquisitions

Restructuring and consolidation or expansion through strategic alliances and mergers & acquisitions is continuing within the cast metal industry. Knight Wendling has been a part of this process through its involvement in a wide range of transactions, providing:

- Acquisition searches

- Commercial and technical due diligence

- Searches for strategic partners

- Setting up joint venture alliances

- Divestment process management

- Post acquisition integration

KNIGHT WENDLING performed reviews of the cast metals industries for government departments in several countries and has worked with national industry associations and regional development agencies on expansion and restructuring of the cast metals sector.

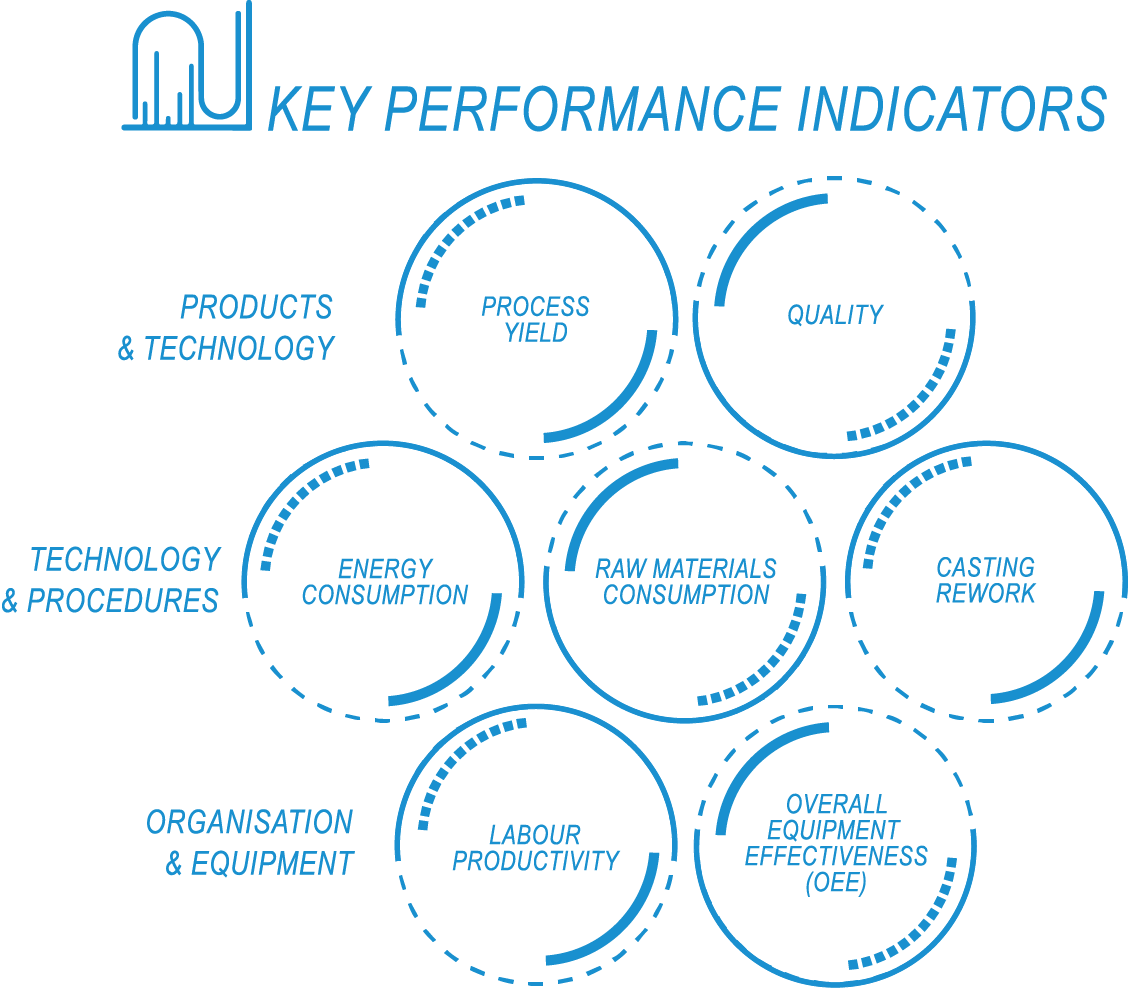

Many of KNIGHT WENDLING's assignments involve operational improvement programs in the foundry. Often our involvement begins with an Operational Audit that examines the facilities and performance levels at key points in the metal casting process.

Operational Expertise

Our foundry experts work to optimize activities in all parts of the casting operation, in areas such as:

- Raw material usage

- Energy efficiency

- Environmental controls

- Plant utilization

- Manpower productivity

- Quality improvement & scrap reduction

- Patterns and tooling

- Facilities planning

- Introduction of new plant and process technology

- Manufacturing systems

- Profit improvement

- Foundry Logistics Simulation

- Productivity Improvement

- Efficiency Improvement

Improvement Potential

From our experience of international best practice, we will identify areas with improvement potential and recommend appropriate measures (with cost/benefit indicators).

Frequently, we are required to assist with the implementation of our recommendations. In this situation, our consultants will work closely with the management and staff of our client to see the project through to the attainment of the required improvements.

In some instances our work with a client takes the form of a long-term engagement in which case KNIGHT WENDLING can also provide staff on an Interim Management basis.